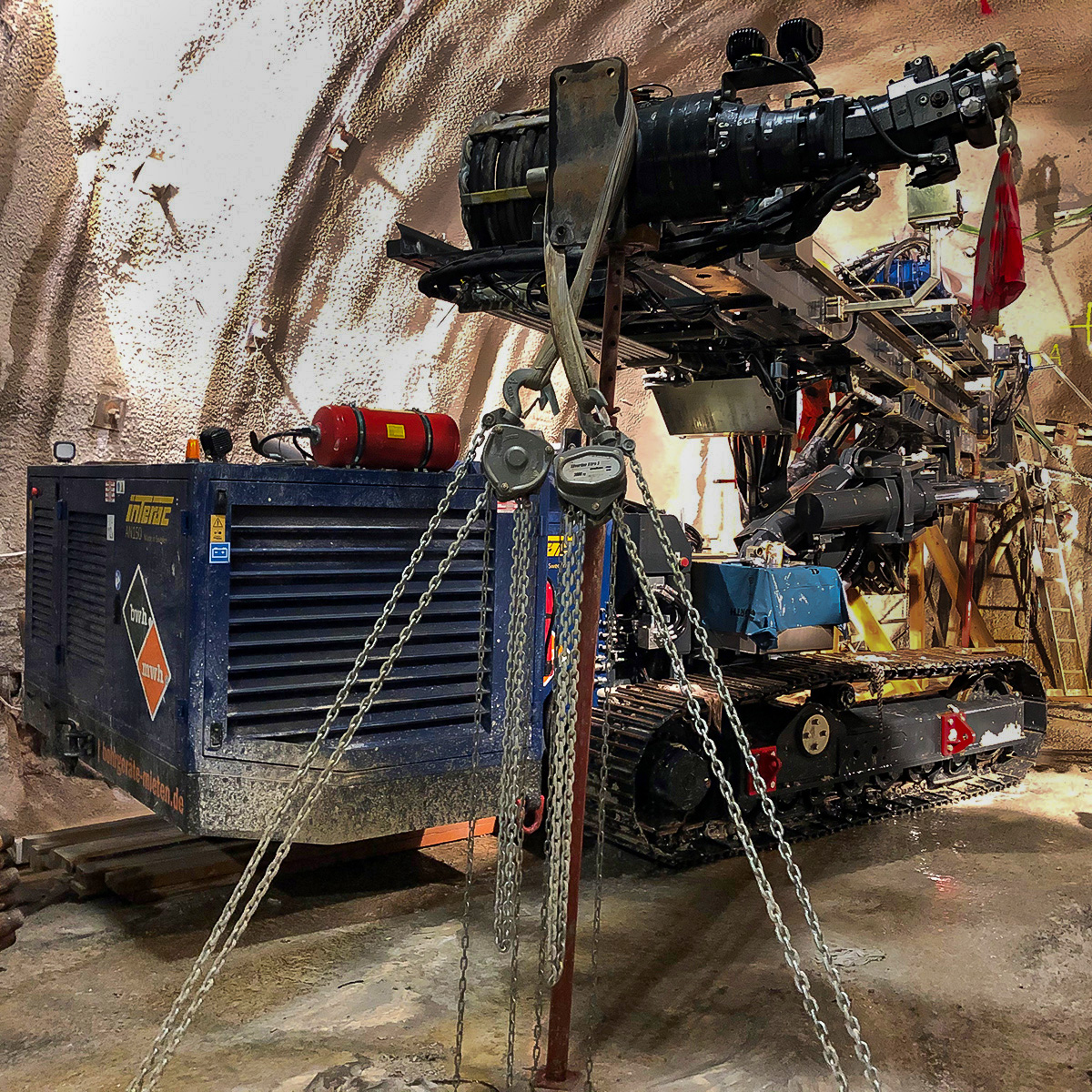

Syfte

Södertälje kanal och sluss byggs om för att kunna hantera allt större fartyg. För att göra detta krävs omfattande grundläggningsarbeten för att säkra slänter och kanalbank, allt för att muddringsarbeten (för att fördjupa kanalen) ska kunna utföras.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

You can adjust all of your cookie settings by navigating the tabs on the left hand side.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

You can adjust all of your cookie settings by navigating the tabs on the left hand side.